Click on the image for a super detailed view.

Important Safety Note: Working on or testing equipment such as the Heathkit HW-101 transceiver and the HP-23 power supply is extremely dangerous since very high voltages are present when the equipment is turned on, and may even be present when the equipment is turned off and unplugged. If at all possible, do all work with the equipment off and unpluggedand be sure that the capacitors are properly discharged before working on the equipment. The operator assumes all risk and liability in such matters! Do not work on this type of equipment unless you are experienced with working around very high voltages!

Some General Comments

On Alignment: Complete alignment instructions for the HW-101

can be found in the HW-101 manual.

However, the instructions in the manual can be confusing at times and often do

not explain the reason for the procedure that is being performed. Also, the

alignment instructions are based on technology typically available in the

1970s. With modern technology, such as frequency counters and inexpensive

digital voltmeters, some of the procedures are much easier.

The alignment instructions given here are an attempt to make the alignment a

bit easier by clarifying the procedure, using modern technology when possible,

and explaining the reason for each procedure.

Receiver Alignment:

Introduction To Receiver

Alignment:

Receivers contain many set-and-forget controls (coils, capacitors,

potentiometers, adjustable resistors etc.) that must be set to their proper

positions. As a result the receiver will exhibit maximum performance, which

includes things such as maximum stability, selectivity, sensitivity, and

accurate display of frequency. The process of making all of these

set-and-forget adjustments is called alignment.

S Meter

Adjustment:

In most situations, the S meter is used to indicate proper alignment, so it

must be set first.

The point of this adjustment is to have the S meter read zero on the 80m band

with a 50 ohm dummy load connected to the input and the RF gain set to its

maximum value.

To adjust the S meter, connect a 50 ohm dummy load (do not use a light

bulb!) to the antenna connector, then set the front panel controls as follows:

DRIVER PRESELECTOR - 12 o'clock position

MIC/CW LEVEL - fully counterclockwise

MODE - LSB

BAND - 3.5

MAIN TUNING DIAL (VFO) - 200

FUNCTION - PTT

RF GAIN - fully clockwise

METER - ALC

AF GAIN - 9 o'clock

Adjust the ZERO ADJ control (on the right side of the chassis) for a zero

indication on the meter.

Initial Heterodyne

Oscillator Coil Alignment:

The output of the heterodyne oscillator for each band must be set to the proper

level. An output that is too high is as bad as an output that is too low.

Adjustment of the heterodyne oscillator coils is perhaps the most

confusing/difficult of all the alignment adjustments. At this point we only do

an initial adjustment. Final adjustment is done

during transmitter alignment.

What Am I Measuring?:

During this adjustment, the bias on the heterodyne crystal oscillator V19A is

measured with a voltmeter. The bias is a direct measure of the oscillator

output, with a higher bias indicating higher output.

What Kind of Voltmeter Should I Use?:

Normally, a bias measurement such as this requires the use of a voltmeter with

a high (11 Mohm) input impedance. Most modern digital meters (even the cheap

ones from, for example, Harbor Freight Tools) meet this requirement, and it is

worth purchasing one if you do not already have such a meter. If absolutely

necessary an older analog meter with a sensitivity of at least 20,000 ohm/Volt

can be used. This is because a relatively low value 4.7 kohm resistor loads the

grid in this particular circuit.

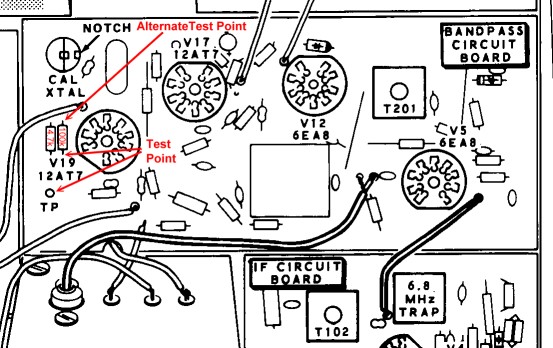

Where Do I Connect The Voltmeter:

One lead of the voltmeter is connected to ground. If you are using a digital

voltmeter, the negative lead goes to ground. If you are using an analog meter,

the positive lead is connected to ground. The other lead is connected to a test

point near V19 on the bandpass circuit board. Look at the bandpass circuit

board from the front and you will find V19 at top left just in front of the

tall crystal calibrator crystal. Immediately to the left of the V19 tube socket

you will see a 100 kohm (brown-black-yellow) resistor and a 4.7 kohm

(yellow-violet-red) resistor. The test point is in the front of these two

resistors and is labeled TP. If there is nothing but a hole where the test

point should be, simply connect to the 100 kohm resistor lead closest to you.

If your voltmeter reads 0V at TP, use the alternate test point, which is the

other end of the 100 kohm resistor. Click on the photo below to see where these

test points are located.

Test Point Locations for

Heterodyne Oscillator Coil Alignment

Click Here To Enlarge

What If The Coil Cover Prevents Some Of The Coils From Being

Adjusted?

The coils should be adjusted with the coil cover in place. If some of

the coils are blocked by the cover, as they were in my HW-101, the holes in the

cover must be enlarged. Click here to find out how to

modify the coil cover and enlarge the holes.

How Do I Make The Adjustment?:

Set the bandswitch to a particular band and locate the coil for that band. Then

make the adjustment by noting the following:

1. You do not necessarily want to adjust each coil for a maximum

reading. A reading that is too high is as bad as a reading that is too

low. What you want is a reading as high as possible between -0.5 V and

-2.0 V, but not exceeding -2.0 V.

2. For each coil you will find a setting that maximizes the reading. If this

reading is between -0.5 V and -2.0 V, then leave the coil set at the maximum

reading.

3. If the maximum reading is larger than -2.0 V, it must be reduced to -2.0 V.

From the peak value, turn the coil in both directions to find out in which

direction the value drops more slowly, then turn the coil in that direction

until the value drops to -2.0 V.

Where Are The Coils Located?:

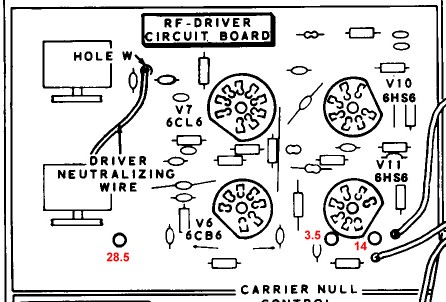

This adjustment must be made for all eight heterodyne oscillator coils. Five of

the coils, 21 MHz, 7 MHz, 29.5 MHz, 29.0 MHz, and 28 MHz, are marked on the

coil cover and are accessed from the bottom of the chassis. The coils for 3.5

MHz, 14 MHz, and 28.5 MHz are marked and adjusted from the top side of the

RF-driver board as shown in the diagram below.

Location of the 3.5, 14, and 28.5

Heterodyne Oscillator Coils

Click Here To Enlarge

Receiver IF

Alignment:

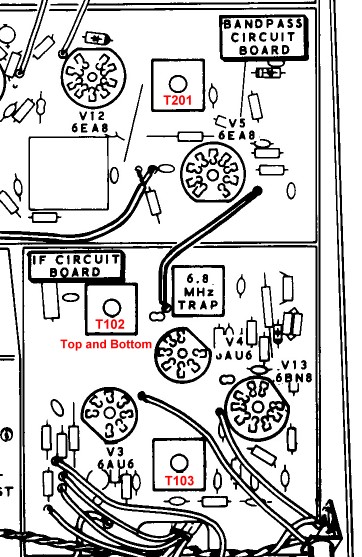

The receiver 3395 kHz IF section must be adjusted for maximum response at 3395

kHz.. This involves adjusting T201 on the bandpass circuit board and T102, and

T103 on the IF circuit board, as shown in the picture below.

Set the front panel controls as follows:

DRIVER PRESELECTOR - 12 o'clock position

MIC/CW LEVEL - fully counterclockwise

MODE - LSB

BAND - 3.5

MAIN TUNING DIAL (VFO) - 400

FUNCTION - PTT

RF GAIN - fully clockwise

METER - ALC

AF GAIN - 9 o'clock

Turn on the calibrator by setting the function switch to CAL and tune in the

calibrator signal for maximum response on the S meter.

When tuning in the calibrator signal, turn the DRIVER PRESELECTOR to make

sure there is a variation in volume. If there is no variation in volume the

signal is a spurious signal and NOT the calibrator signal.

Reset the DRIVER PRESELECTOR to the 12 o'clock position.

Adjust T201 for maximum S meter reading/maximum volume.

Adjust the top and bottom slugs of T102 for maximum S meter reading/maximum

volume. To adjust the bottom slug you must have an alignment tool that will

pass through the top slug and then fit into the bottom slug.

Adjust T103 for maximum S meter reading/maximum volume.

Touch up all three for maximum S meter reading/maximum volume.

Receiver IF Alignment

Location of T201, T102, and T103

Click Here To Enlarge

General Comments On

Aligning An Analog Frequency Display:

In many receivers or transmitters a parallel resonant circuit (tuned circuit)

is coupled to an analog readout, typically a slide rule display or, as in the

HW-101, a rotary display. The tuned circuit usually consists of a variable

capacitor as the main controlling element in parallel with a coil that can be

adjusted and then left in place. A trimmer capacitor is also in parallel with

the variable capacitor, either mounted directly on the capacitor or as a

separate unit.

The goal in aligning such a system is to find the particular combination of

trimmer capacitor setting and coil setting that will cause the display to read

correctly at two different frequencies typically near the opposite ends of the

display (when adjusting a local oscillator), or for S meter readings to be

maximized at the calibration frequencies (when adjusting an RF amplifier).

Signals at the two desired frequencies must be available from a frequency

generator/synthesizer or a crystal calibrator.

It is important to note that in some cases, such as the HW-101, the actual

resonant frequency of the tuned circuit is lowest when the analog scale

indicates the highestfrequency! For example, in the HW-101, the VFO

frequency is lowest (5.000 MHz) when the main tuning is at 500, and highest

(5.500 MHz) when the main tuning is at 0. This apparent discrepancy occurs

because of the mixing scheme in use. Regardless, the frequency of the tuned

circuit is lowest when the variable capacitor is meshed, and highest when it is

unmeshed.

To align the system, an iterative procedure is used. The coil and trimmer

capacitor are adjusted a little bit each time, and the procedure is used over

and over again until the final settings are found.

Here is the general procedure:

1. Set the analog scale and the frequency generator to the calibration

frequency where the capacitor plates are more meshed.

Adjust the coil to tune in the calibration signal and/or maximize the S

meter reading.

2. Set the analog scale and the frequency generator to the calibration

frequency where the capacitor plates are less meshed.

Adjust the trimmer capacitor to tune in the calibration signal and/or

maximize the S meter reading.

3. Repeat this procedure over and over again until the calibration signals

appear at the correct positions on the analog scale.

It is usually necessary to repeat this procedure many times until the

calibration signals appear where they should on the analog scale or the S meter

readings are maximized. Sometimes the procedure can be sped up by going "a

little too far" with the trimmer capacitor on each run.

VFO Alignment:

Make sure the transceiver has warmed up for at least 30 minutes before making

the following adjustments.

Before aligning the VFO, read the previous section General Comments On Aligning An Analog Frequency

Display, keeping in mind that the HW-101 VFO is an oscillator and that the

VFO frequency goes down as the main tuning display goes up.

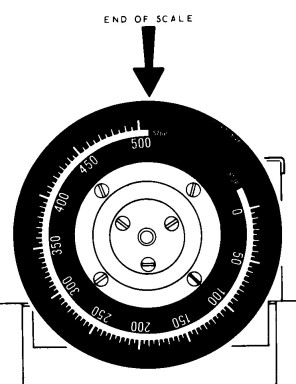

Before actually aligning the VFO, the rotary scale must be set properly on the

main tuning shaft. When the main tuning control is rotated counterclockwise as

far as it will go (do not force it) the scale should be positioned as shown in

the diagram below, with the end of the scale (the white bar) directly under the

indicator line.

The scale is connected to the main tuning shaft via a slip clutch. The scale

can be held in place by pressing and holding the Zero Set button. The main

tuning knob can then be turned to rotate the main tuning shaft while the scale

is held in place. This alters the position of the scale relative to the shaft.

To Align The Frequency Scale:

Rotate the main tuning dial counterclockwise until it stops. Do not force it.

If the end of the scale is too far to the right, back up the main tuning knob

until the reading is about 475. Press and hold Zero Set while you turn the main

tuning knob about 1/4 turn to the right (clockwise). Recheck the setting. If

still too far to the right, repeat the process until the scale is positioned

correctly.

If the scale is too far to the left, back up the main tuning dial until the

reading is about 475. Press and hold Zero Set while you turn the main tuning

knob about 1/4 turn to the left (counterclockwise). If still too far to the

left, repeat the process until the scale is positioned correctly.

Proper Position of Analog Scale When

Main Tuning Dial

Is Turned Counterclockwise As Far As It Will Go

Click Here To Enlarge

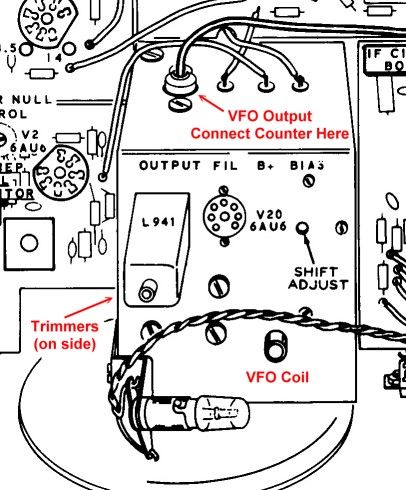

To Align The VFO Using A Frequency Counter:

Since the VFO is an oscillator that has a buffer stage to isolate it, the

easiest way to align the VFO is to use an accurate frequency counter. There is

an RCA connector on the rear of the VFO housing. Disconnect the cable currently

in the jack and connect the frequency counter to the jack. See the diagram

below to see where to connect the counter and for the location of the VFO

adjustments.

1. Turn the main tuning dial counterclockwise until it reads exactly 500.

Adjust the VFO coil so that the counter reads exactly 5000 kHz.

2. Rotate the main tuning dial clockwise until it reads exactly 0. Adjust the

trimmer capacitor(s) on the side of the VFO enclosure so that the counter reads

exactly 5500 kHz.

3. Reset the dial to 500 and readjust the VFO coil so the counter again reads

5000 kHz.

4. Reset the dial to 0 and adjust the trimmer(s) so that the counter again

reads 5500 kHz.

5. Repeat this procedure as many times as necessary until the counter reads

5000 kHz at the 500 mark and 5500 kHz at the 0 mark. This could take quite a

few repetitions. Sometimes the procedure can be sped up by going "a

little too far" with the trimmer capacitor on each run.

To Align The VFO Using The Crystal Calibrator:

Lacking a frequency counter, the transceiver crystal calibrator can be used.

For highest accuracy the crystal calibrator should be calibrated before

aligning the VFO. Crystal calibrator alignment is

explained in the transmitter alignment section. Note that the Heathkit manual

is not concerned with with prior calibration of the crystal calibrator, so this

step may not be necessary. See the diagram below for the location of the VFO

coil and the calibration trimmer capacitors.

1. Set up the transceiver to receive on the 3.5 MHz band.

2. Turn on the calibrator by setting the mode switch to CAL and find the

calibrator signal at the top end of the main tuning dial. This should be

somewhere above 475 on the dial.

3. Adjust the tuning for zero beat and, while carefully adjusting the VFO coil,

"walk" the calibrator signal until zero beat occurs at 500 on the

dial.

4. Rotate the tuning dial to the the bottom of the scale and find the

calibrator signal around 0 at the bottom of the scale. This should be somewhere

below 25 on the dial.

5. Adjust the tuning for zero beat and, while carefully adjusting the trimmer

capacitor(s), "walk" the calibrator signal until zero beat occurs at

0 on the dial.

6. Go back up to the top of the scale and find the calibrator signal around

500. Repeat step 3.

7. Go back to the bottom of the scale and find the calibrator signal around 0.

Repeat step 5.

8. Repeat this procedure until the calibrator signal is zero beat at the 0 mark

and the 500 mark. This could take quite a few repetitions.

Since it is possible, in an extreme case, to be 100 kHz off, it is a good idea

to tune in a signal of known frequency and make sure it comes in at the proper

place on the dial.

Location of VFO Adjustments and

Connections

Click Here To Enlarge

Driver Grid And Plate

Coil Alignment:

Make sure the transceiver has warmed up for at least 30 minutes before making

the following adjustments.

Though the driver grid and plate coils are used both by the receiver and the

transmitter, they are adjusted in receive mode. The adjustments are easy to

make. However, because of the circuit design, the adjustments interact with

each other . For example, changing the adjustment of the 21.0 MHz coils will

also affect the 14.0 MHz and 7.0 MHz bands. As a result, they must always be

adjusted in the proper order. This also means you can't just touch up

the coils for one band without redoing all of the others.

The 3.5 MHz coils are adjusted first, followed by the 29 MHz, 21 MHz, 14 MHz,

and 7 MHz coils. They must be adjusted in this order.

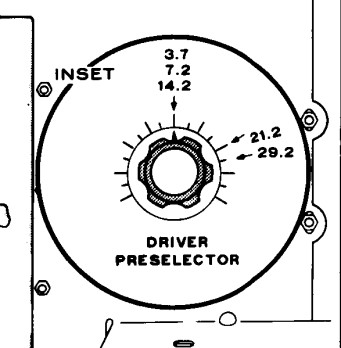

The actual frequencies used for adjustment are 3.7 MHz, 29.2 MHz, 21.2 MHz,

14.2 MHz, and 7.2 MHz. When adjusting any set of coils, the driver

preselector control must be set to the proper position as shown below:

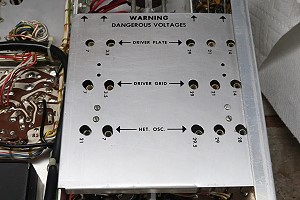

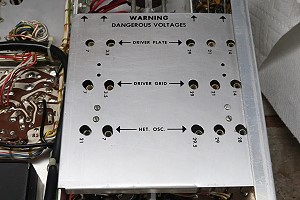

Preselector Settings for

Driver Grid And Plate Coil Alignment

Click Here To Enlarge

Connect a 50 ohm dummy load to the transceiver antenna connector.

Set the front panel controls as follows:

DRIVER PRESELECTOR - 12 o'clock position

MIC/CW LEVEL - fully counterclockwise

MODE - LSB

BAND - 3.5

MAIN TUNING DIAL (VFO) - 200

FUNCTION - PTT

RF GAIN - fully clockwise

METER - ALC

AF GAIN - 9 o'clock

When tuning in any calibrator signal, turn the DRIVER PRESELECTOR to make

sure there is a variation in volume. If there is no variation in volume the

signal is a spurious signal and NOT the calibrator signal. When you are

finished verifying the calibrator signal, reset the DRIVER PRESELECTOR control

to the proper position as shown in the picture above.

Turn on the crystal calibrator by moving the function switch to CAL.

With the band selector in the 3.5 MHz position tune in the calibrator signal

near the 200 position on the main tuning dial. Adjust the main tuning dial for

a maximum S meter reading.

Be sure the DRIVER PRESELECTOR is in the 3.5 position as shown above and adjust

the coils marked 3.5 for maximum S meter reading.

Change the band selector to the 29.0 MHz position. Tune in the calibrator

signal near the 200 position on the main tuning dial and adjust for a maximum S

meter reading..

Be sure the DRIVER PRESELECTOR is in the 29.2 position as shown above and

adjust the coils marked 29 for a maximum S meter reading.

Change the band selector to the 21.0 MHz position. Tune in the calibrator

signal near the 200 position on the main tuning dial and adjust for a maximum S

meter reading..

Be sure the DRIVER PRESELECTOR is in the 21 position as shown above and adjust

the coils marked 21 for a maximum S meter reading.

Change the band selector to the 14.0 MHz position. Tune in the calibrator

signal near the 200 position on the main tuning dial and adjust for a maximum S

meter reading..

Be sure the DRIVER PRESELECTOR is in the 14 position as shown above and adjust

the coils marked 14 for a maximum S meter reading.

Change the band selector to the 7.0 MHz position. Tune in the calibrator signal

near the 200 position on the main tuning dial and adjust for a maximum S meter

reading..

Be sure the DRIVER PRESELECTOR is in the 7 position as shown above and adjust

the coils marked 7 for a maximum S meter reading.

Remember, these adjustments must always be done in sequence since they interact

with one another.

Transmitter Alignment:

Introduction To

Transmitter Alignment:

Because many receiver circuits are shared with the transmitter, you must

align the receiver first before aligning the transmitter.

When making any transmitter adjustments, be sure a 50 ohm dummy load (do NOT

use a light bulb) is connected to the transceiver.

Transmitter Bias

Adjustment:

The first transmitter adjustment is to set the bias on the final amplifier

tubes to the correct value. This is done by putting the transmitter in transmit

mode while in LSB mode with no drive on the final amplifier tubes and turning

the BIAS control (on the right side of the transceiver) so that the cathode

current reads the correct value.

Important Note: Placing the transmitter in transmit mode for more than a few

seconds with the bias at the wrong value can damage the final amplifier tubes.

Set the front panel controls as shown below:

DRIVER PRESELECTOR - 12 o'clock position

MIC/CW LEVEL - fully counterclockwise

FINAL (round knob) - to 10 o'clock

FINAL (lever knob) - to 4 o'clock

MODE - LSB

BAND - 3.5

MAIN TUNING DIAL (VFO) - 200

FUNCTION - PTT

METER - PLATE

Press the microphone button (or short the PTT pin on the microphone jack to

ground) and turn the bias control (on the right side) of the Transceiver to set

the meter needle at the "3" mark on the meter scale. There is an

arrow above the "3" on the meter scale to help identify the correct

setting.

Carrier Isolation Amplifier

Alignment:

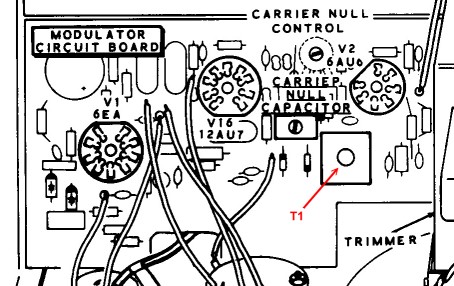

In this step, transformer T1 at the output of the balanced modulator is

adjusted for maximum response.

Be sure a 50 ohm dummy load (do NOT use a light bulb) is connected to the

Transceiver.

Set the controls as shown above for Transmitter Bias

Adjustment and verify that the transmitter bias is set correctly.

then:

Set the METER switch to REL PWR and press the microphone button (or short the

PTT pin on the microphone jack to ground). The meter should read zero.

Set the MODE switch to the TUNE position and slowly turn the MIC/CW LEVEL

control clockwise until there is an indication of RF output of not more than 6

on the meter

Adjust the DRIVER PRESELECTOR and peak the RF output. Reduce the MIC/CW LEVEL

to keep the reading below 6.

Adjust the FINAL tune (round knob) and peak the RF output. Reduce the MIC/CW

LEVEL to keep the reading below 6.

Adjust the MIC/CW LEVEL control for an RF output of not more than 3 on the

meter.

Adjust transformer T1 for a maximum reading on the meter.

Readjust the MIC/CW LEVEL control for an RF output of not more than 3 on the

meter.

Again adjust transformer T1 on the modulator circuit board for a maximum

reading on the meter. See the diagram below.

Set the MODE switch back to LSB.

Location of T1

Click Here To Enlarge

Preliminary Final

Amplifier Neutralization:

Neutralization is one of the most important transmitter adjustments. If not

neutralized properly, the transmitter can break into self oscillation, causing

illegal spurious emissions and distortion.

Neutralization is required because unintentional/unavoidable positive feedback

through the tube being neutralized can cause it to self oscillate. To prevent

this self oscillation, some of the output is intentionally fed back to the

input out of phase to cancel the undesired positive feedback. Since the

amount of feedback needed varies with the particular tube(s) and the

surrounding circuitry, it must be done for every individual case. If the

tube(s) are changed or the circuit is rearranged, it must be redone.

For a power amplifier such as that in the HW-101, there is an easy way to tell

if the circuit is neutralized:

When the plate tuning (FINAL control on the HW-101) is adjusted, a dip

in the plate/cathode current will be observed. When looking at the RF output,

there will be a peak in the RF output.. When the dip in the

plate/cathode current occurs at the same setting of the FINAL control

where the peak in the RF output occurs, the amplifier is neutralized.

When making this adjustment, you can use the REL. POWER and PLATE positions of

the METER switch to read the output power and cathode current respectively.

This, however, requires constantly switching the meter from one position to

another. It is much easier to use an SWR meter or wattmeter connected to the

Transceiver output to read the RF output. The METER switch can then be left in

the PLATE position.

Theoretically, the neutralization should not depend on frequency, but in

reality it does. In this case, the final amplifier will initially be

neutralized at 3.5 MHz. Then, after neutralizing the driver stage, it will be

touched up at 14 MHz.

As a first step, Heathkit says to rotate the neutralizing capacitor fully

clockwise until resistance is felt, and then turn it counterclockwise one full

turn. But this is for a newly built HW-101. For an HW-101 that has been in

service, it is safe to assume that it is already near proper neutralization,

and to avoid this initial step.

Location

of Neutralizing Capacitor

and Driver Neutralizing Wire

Click Here To Enlarge

The neutralizing capacitor is mounted on the front of the final amplifier

cage. See the figure above.

The following procedure may seem confusing, but once you do it a couple of

times you will understand the general idea.

When performing the following steps, keep the Transceiver at full power output

for the minimum time necessary. Then place the MODE switch at LSB and

let the final stage tubes cool for at least 30s before continuing.

To perform the initial neutralization:

1. Be sure the controls are set up as in the previous step,

Carrier Isolation Amplifier Alignment.

2. Turn the MODE switch to TUNE and adjust the MIC/CW LEVEL control and FINAL

tune control for maximum output (either on the REL. PWR meter or on the

SWR/wattmeter). Go back to LSB and allow the finals to cool. Carefully note

the position of the FINAL tune control.

3. Be sure the METER switch is set to PLATE, and activate TUNE again. While

TUNE is activated, move the FINAL tune control carefully back and forth about

the position noted earlier and verify that the plate current is at a minimum

in the same position as when the output is a maximum. Go back to LSB.

4 If maximum output and minimum plate current do not occur at the same setting

of the FINAL tuning control, make a mental note of how far they are apart on

the FINAL tuning control. Note the position of the neutralizing capacitor, then

rotate it a small amount (1/16 - 1/8 turn) clockwise and repeat the previous

steps 2 and 3.

5. If the maximum and minimum are farther apart on the FINAL tuning control,

you went the wrong way with the neutralizing capacitor. Return it to its

starting point and then go counterclockwise on the neutralizing capacitor. If

the maximum and minimum got closer together, rotate the neutralizing capacitor

a little further clockwise and recheck.

6. Continue the previous steps until you find the position of the neutralizing

capacitor where maximum output and minimum plate current occur at the same

setting of the FINAL tuning control.

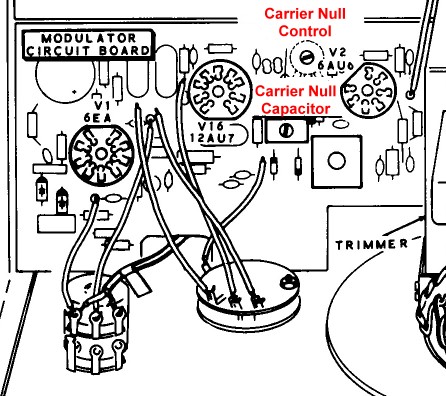

Carrier Null

Adjustment:

The carrier null adjustment reduces the carrier in the output to the lowest

possible level. This is a compromise adjustment, because the best setting is

different for LSB and USB. A variety of indicators can be used to indicate the

carrier level in the output. These include the following:

1. An RF voltmeter connected to the output

2. An oscilloscope connected to the output

3. Listening to the output on a nearby receiver tuned to the carrier frequency

4. An RF wattmeter/SWR meter connected to the output

5. The REL. PWR meter on the HW-101

For best results, either an RF voltmeter, oscilloscope, or listening on a

receiver should be used. Lacking these, adequate results can be obtained using

the REL. PWR meter.

In all cases a 50 ohm dummy load (not a light bulb) must be connected to the

output. If you are using an RF voltmeter or oscilloscope, use a "T"

connector on the output so both the dummy load and voltmeter or oscilloscope

are connected at the same time. If you are using a receiver, do NOT connect it

to the output!

:

1. Tune the transceiver up on the 80m band at 3700 kHz.

2. Set the controls as follows:

METER - REL. PWR

FUNCTION - PTT

MODE - LSB

MIC/CW LEVEL - fully counterclockwise.

3. Activate PTT and adjust the carrier null control for minimum RF

output.

4. Adjust the carrier null capacitor for minimum RF output.

5. Switch to USB and repeat steps 3 and 4.

6. Repeat the above steps until the RF output is about the same both in LSB and

USB. This is a compromise. You want minimum RF output, but you want it to be

the same on LSB and USB.

See the diagram below for the location of the carrier null control and carrier

null capacitor.

Location

of Carrier Null Control

and Carrier Null Capacitor

Click Here To Enlarge

Final Heterodyne

Oscillator Coil Alignment:

Before you perform this step, be sure you have done the initial heterodyne oscillator alignment.

Be sure a 50 ohm dummy load (do not use a light bulb) is connected to the

transceiver.

To perform the final heterodyne oscillator coil alignment:

1. Set the METER switch to REL. PWR

2. Set the BAND switch to 3.5 and the MAIN TUNING dial to 200 (3700 kHz).

3. Tune up the transceiver on 3700 kHz for maximum output as indicated on the

meter.

3. Switch the MODE switch to TUNE and use the MIC/CW LEVEL control to obtain a

reading between 3 and 9 on the meter.

4. Adjust heterodyne oscillator coil 3.5 for maximum output.

5. Repeat the following adjustment for each position of the BAND switch, except

adjust the coil with the same number as the BAND switch. Five of the coils, 21

MHz, 7 MHz, 29.5 MHz, 29.0 MHz, and 28 MHz, are marked on the coil cover and

are accessed from the bottom of the chassis. The coils for 3.5 MHz, 14 MHz, and

28.5 MHz are marked and adjusted from the top side of the RF driver board.

Driver

Neutralization:

In the HW-101, the driver stage must also be neutralized. The neutralizing

capacitor is a white wire attached to the frame of the front driver preselector

capacitor that runs through a hole in the RF Driver circuit board. For the

location of the wire, see the figure under

preliminary final amplifier neutralization. Note that the frame of this

capacitor is not directly grounded. Rather, it is connected to ground

through a 100 ohm resistor. When the white wire is inserted through the circuit

board, the wire is near the plate lead of the 6CL6 driver tube. The capacitance

between the two forms the driver neutralizing capacitor, and it is adjusted by

varying the amount of wire stuck through the hole. Inserting more wire through

the hole increases the capacitance. Pulling the wire out decreases the

capacitance. Crude, but it works.

It is not possible to monitor the output of the driver or the driver plate

current, so proper neutralization must be determined differently than in the

case of the final amplifier. For the driver, proper neutralization is indicated

by the lack of erratic behavior when the DRIVER PRESELECTOR is adjusted.

To neutralize the driver:

Set the BAND switch to 21.0 MHz

Set the MAIN TUNING to read 21.2 MHz

Go into TUNE mode and adjust the DRIVER PRESELECTOR, FINAL TUNE, and LOAD

controls for maximum RF output.

Turn the DRIVER PRESELECTOR control back and forth to see if this produces a

smooth peaking in RF output.

If turning the DRIVER PRESELECTOR control causes ragged or uneven changes in

the RF output, readjust the position of, or bend, the free end of the

driver neutralizing wire to produce a smooth

peaking in the RF output.

Final Amplifier

Neutralization Touch Up:

Repeat the preliminary final amplifier

neutralization, except perform the procedure at 14.2 MHz, where the

adjustment is more sensitive.

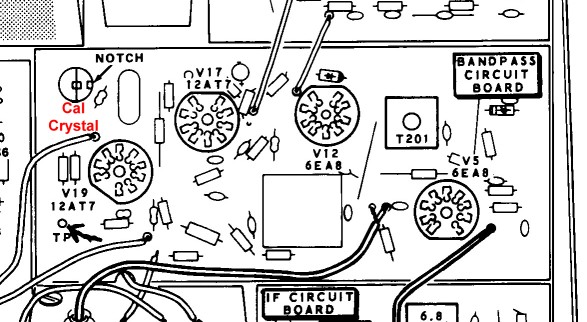

Crystal Calibrator

Alignment:

In this adjustment, the crystal calibrator is set to a frequency of exactly

100,000.0 Hz. You might be tempted to use a frequency counter to make this

adjustment, but unless the counter is a laboratory quality instrument with a

resolution of 0.1 Hz or 0.01 Hz it will not be accurate enough. The calibrator

frequency must be accurate within a fraction of a Hz. This is most

easily done be comparing a high harmonic of the calibrator signal to another

signal of known frequency, for example WWV. You will need a receiver capable of

receiving WWV at 10 MHz or 15 MHz.

To calibrate the crystal calibrator:

1. Use your receiver to tune in WWV at 10 MHz or 15 MHz. This may be possible

only at certain times of the day.

2. Be sure that the MIC/CW LEVEL control is fully counterclockwise so

there is no way the transmitter can put out any signal.

3. Connect a random length of wire from the transceiver output to the external

receiver antenna.

4. Tune the external receiver to WWV at 10 MHz or 15 MHz.

5. Set the FUNCTION switch to CAL and carefully adjust the CAL CRYSTAL

capacitor on the bandpass circuit board to zero beat the calibrate signal with

the WWV signal. The location of the Cal Crystal capacitor is shown in the

diagram below. Wait until there is no modulation present on WWV to make this

adjustment. Listen very carefully. When you get close to the proper adjustment

you will hear the noise in the background pulsate. Try to get the pulsation to

stop if possible. If you can't get it to stop, just get it to go as slow as

possible.

Location of

Crystal

Calibrator Adjustment

Click Here To Enlarge

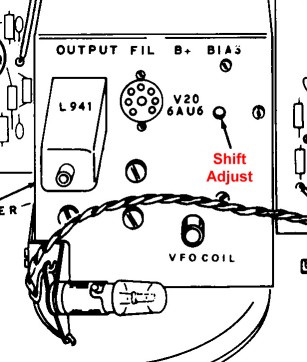

VFO Shifter

Adjustment:

When switching from LSB to USB, the carrier oscillator frequency is changed.

This will cause the reading of the MAIN TUNING dial to read incorrectly unless

the VFO is also shifted when changing from LSB to USB. This is accomplished be

electronically switching a trimmer capacitor in and out when changing from LSB

to USB. This capacitor is mounted on the top side of the VFO enclosure.

Do NOT confuse it with the trimmer capacitors on the left side of the

enclosure.

To adjust the shift capacitor:

1. Adjust the MAIN TUNING dial to 200 kHz and the BAND switch to 3.5.

2. Set the FUNCTION switch to CAL to turn on the crystal calibrator.

3. Turn the MODE switch to USB.

4. Carefully zero beat the calibrator signal. Use the MAIN TUNING dial and peak

the DRIVER/PRESELECTOR control.

5. Set the MODE switch to LSB. Be careful not to touch the MAIN TUNING dial.

Note that the calibrator signal may or may not be zero beat in the LSB

position.

6. Turn the SHIFT ADJUST on the top of the VFO for an exact zero beat in the

LSB mode. See the diagram below for the location of the shift adjust capacitor.

7. Recheck for zero beat in the USB mode and repeat the adjustment until you

have zero beat in both LSB and USB at the same setting of the MAIN

TUNING dial.

Location

of VFO Shift Adjust Capacitor

Click Here To Enlarge

Back to Dr. Greg Latta's

Electrical Engineering and Amateur Radio Pages

Back to Dr. Greg Latta's

Electrical Engineering and Amateur Radio Pages

If you have any questions or

comments, you can send E-Mail to Dr. Greg Latta at

glatta@frostburg.edu

If you have any questions or

comments, you can send E-Mail to Dr. Greg Latta at

glatta@frostburg.edu