The Johnson Viking Ranger

by Greg Latta, AA8V

Restoration

Important Safety Note: Working on or testing equipment such as

the Viking Ranger is extremely dangerous since very high voltages are present

when the equipment is turned on, and may even be present when the equipment

is turned off and unplugged. If at all possible, do all work with the

equipment off and unpluggedand be sure that the capacitors are

properly discharged before working on the equipment. The operator assumes

all risk and liability in such matters! Do not work on this type of equipment

unless you are experienced with working around very high voltages!

Restoration:

Introduction:

On the evening of November 1st, 2013 I was on the 80m band with my 2E26/813

transmitter and I wound up working W3PH, Paul Heller, in Deep Creek Lake, MD.

During the QSO I mentioned to Paul that I did a lot of building with vacuum

tubes. Paul then mentioned that he had a Johnson Viking Ranger transmitter that

he was willing to give me for free if I wanted it. He had purchased it at a

hamfest some 30 years ago with the intention of restoring it, but had never

gotten to it. It had been sitting in a plastic bag in his shed all those years.

After a couple of e-mails Paul brought the Ranger to my house two days later,

and on November 3rd, 2013 I was the proud owner of a rather sorry looking

Viking Ranger. It was in terrible shape and full of sawdust and mouse

droppings, but the mice had simply moved in and hadn't eaten any of the rig.

With a lot of work it looked like it could be cleaned up and put back on the

air.

After six months of painstaking restoration work the transmitter went back on

the air Wednesday, June 11th, 2014. I made the first QSO with crystal control

and then switched to VFO control from my external digital VFO. I now have the

Ranger on the air on a regular basis. It sounds great, looks great, and was

well worth all of the time I spent working on it.

Links To Some Currently Available Parts For

The Johnson Ranger:

After I finished restoring my Ranger, I made a list a parts that I had

purchased during the restoration as well as parts suggested to me by others.

The result is the table below. At the time of writing (October 2021) the links

shown are valid, though they may obviously change with time, and parts

specifications may also change. Still, it is probably the most valuable

resource on this web page. I hope you find it useful.

Links To Some Currently Available Parts For

The Johnson Ranger

| Description |

Link |

Source |

| High B+ Electrolytic Capacitor C77 |

|

|

| 33uf 450V Electrolytic Capacitor - 2 Required |

598-336TTA450M

|

Mouser Electronics |

| 270k Ohm 3W Metal Film Resistor - 2 Required |

594-5093NW270K0J |

Mouser Electronics |

| Shunt each capacitor with a 270k resistor and place

the capacitors in series. Use in place of C77. |

|

|

| Low B+ Electrolytic Capacitor C78 |

|

|

| C78 - 47uf 450V Electrolytic Capacitor |

598-476TTA450MRZ

|

Mouser Electronics |

| Bias Supply Electrolytic Capacitors C90A and

C90B |

|

|

| C90A/C90B Replace with a single 30uf 150V

Electrolytic Capacitor |

75-TVA1412 |

Mouser Electronics |

| Speech Amplifier Electrolytic Capacitors C50A/B

and C59A/B |

|

|

| C50A/B Replace with two individual 10uF 50V

units |

598-106TTA050M

|

Mouser Electronics |

| C59A/B Replace with two individual 15uf 150V

units |

75-TE1508.1 |

Mouser Electronics |

| Drive Control R13: |

|

|

| R13 - Drive Control - 25k Ohm 5 Watt |

774-026TB32R253B1A1 |

Mouser Electronics |

| HV Power Resistor R35: |

|

|

| R35 - HV Bleeder and Voltage Divider - 20k Ohm 50W

Wirewound With Tap |

588-D50K20KE

|

Mouser Electronics |

| Mounting Brackets for R35 - Two Required |

588-9E

|

Mouser Electronics |

| Line Cord And Fuse: |

|

|

| 18-3 Line Cord - 2m (6 ft 7 in) |

562-311007-01 |

Mouser Electronics |

| Single Fuse Holder |

534-3536 |

Mouser Electronics |

| Pilot Lamps: |

|

|

| #51 Pilot Lamps |

560-51 |

Mouser Electronics |

| Speech Amplifier Modification: |

|

|

| 0.01uf/400V film capacitor - Replacement for C52 To

Increase Audio Bass Response |

75-MKT1813310404

|

Mouser Electronics |

| Front Panel Frequency Dial And Escutcheon

Seal: |

|

|

| Radio Daze Frequency Dial For the Viking Valiant and

Viking Ranger |

SKU:

DS-A691 |

Radio Daze |

| Rubber Seal For The Escutcheon - Universal U Channel

Rubber Seal Strip 1/32" Opening Edge Trim All Weather Protector Strip

(10ft) - |

Universal

U Channel Rubber Seal Strip |

WalMart |

| White Knob Pointers: |

|

|

| White Knob Pointers |

Deutsch

114017 Sealing Plug Bag of 10 |

Electrical Depot |

| VFO Input Modification: |

|

|

| 8-Pin Octal Plug - For VFO Input Modification |

P-SP8-500 |

Antique Electronic Supply |

| 6AX5 And 5R4 Rectifier Tube Replacement With

Diodes Modification: |

|

|

| Octal Tube Base - For 6AX5 And 5R4 Diode Replacement

Modification |

P-SP8-476 |

Antique Electronic Supply |

| 1N4007 1000V Diode - For 6AX5 And 5R4 Diode Replacement

Modification |

P-Q1N4007 |

Antique Electronic Supply |

| Modulator Tubes: |

|

|

| 6L6GC Modulator Tube - Pair |

Tung6L6STRMD

|

Sweetwater Sound |

Initial Cleaning:

As received the transmitter was very dirty and certain areas were full of mouse

droppings and sawdust. A thorough vacuuming with the shop vac and a chip brush

cleaned everything out. First inspection showed that the mice had simply moved

in and had not eaten anything. No frayed wires or other such damage was found,

and there was no corrosion on the chassis, just the usual dirt that would be

expected after almost 60 years.

Tube Testing:

The tubes were removed, making note of which particular socket each 6CL6 and

12AU7 was in. Noting the particular tube socket guarantees that each tube

goes back into the same socket, since alignment sometimes depends on the

particular tube, and there are two 6CL6 and 12AU7 tubes in the Ranger.

The tubes were tested in an Eico dynamic tube tester, and some were found to be

weak. These were replaced with tubes that I already had in stock. The 6AX5GT

rectifier showed some heater to cathode leakage, but it was high enough that it

would not cause any problems. The 6146 final amplifier tube tested OK, but the

only real way to test an RF amplifier tube is by actually using it, and that

would have to wait until later.

Testing The Power Transformer:

The power transformer is one part in a transmitter that is not easy to replace.

If the transformer is defective, then there is not much point in restoring the

transmitter, so testing the transformer was the first order of business after

testing the tubes.

The worst thing one can do is to plug in the transmitter and turn it on, hoping

for the best. This is a sure road to disaster. The transformer or filter

capacitors could be shorted, leading to at best a blown fuse and at worst a

fire. Instead, thorough checks should first be made with an ohmmeter to check

for shorts and other problems before the transmitter is even plugged in.

Filter capacitors should be checked for shorts, and also with a capacitor

tester if possible to see if they have the correct capacitance.

After thorough checks with an ohmmeter, all tubes were removed. In the case of

the Ranger, removing the rectifier tubes also disconnected the transformer

secondary from the rest of the B+ circuits, allowing me to independently check

the transformer and transformer primary circuit.

The transmitter was plugged into a VARIAC (variable AC source)

and a voltmeter was placed across the high voltage secondary. The VARIAC was

set for 10% (about 12V), and the transmitter was turned on. The voltage on the

high voltage secondary was observed to be 10% of the expected value. The other

secondaries were also checked, and all showed 10% of the expected value. The

VARIAC was slowly increased to 25%, 50%, 75% and finally 100% with checks on

the secondary voltages each time to confirm proper operation. No other problems

were observed. The transformer appeared to be OK.

Checking The Filament Circuits:

After the power transformer was tested, all tubes except the rectifier tubes

were plugged into their sockets and the transmitter was turned on. All of the

tube filaments should have lit up, but quite a few did not. After checking the

schematic and the manual it was found that unless the 9-pin accessory plug was

plugged in, some of the tubes were disconnected from the filament supply.

Inserting the accessory plug cured the problem and all of the tubes lit up,

confirming proper operation of the filament circuits.

Testing The B+ and Bias Circuits

To test the B+ and bias circuits, all of the tubes except the rectifiers (5R4,

6AX5, and 6AL5) were removed. The filter capacitors in the high B+ (C77)

low B+ (C78)

and bias (C90A and

C90B) circuits were tested with an ohmmeter and capacitor tester and found

to be OK. A jumble of resistors used to replace R35 was also removed. The line

voltage was then brought up slowly on the VARIAC while the output of these

supplies was tested. All seemed to produce full output when the VARIAC was

brought all the way up, and no overheating was observed anywhere in the

transmitter.

However, there was a problem in the the plate current meter indicated plate

current even though no other tubes were in the transmitter. This was initially

a concern, but it turns out that this is normal. The final amplifier/clamper

tube circuit is wired so that R15, the 30kohm screen dropping resistor, will

draw current through the plate current meter even when the clamper tube and

final tube are not installed. Thus, the power supplies, and all of the

power supply distribution circuits throughout the transmitter, were OK.

Some General Comments On Replacing

Electrolytic Capacitors:

Electrolytic capacitors contain an electrolyte that can dry out over the years.

They can still test and function fine if they contain only a fraction of the

electrolyte. When a vintage radio is first brought back on line the

electrolytic capacitors may function fine at first. However, after some use the

heat from the equipment may dry out what is left of the electrolyte and then

they fail.

In the long run, it is best to eventually replace all of the

electrolytic capacitors (called "recapping") in a piece of vintage

equipment. The needed capacitors can all be purchased and installed at the same

time. This saves shipping costs and avoids having to open up the equipment

multiple times.

To obtain a high enough voltage rating power supply capacitors may have to be

replaced with multiple identicle units in series with appropriate equalizing

resistors across each, as was done for C77. For

power supply capacitors a higher capacitance and/or voltage rating is OK, as

was done for C78.

For electrolytic capacitors in speech amplifiers and audio circuits, such as

C50A/B and C59A/B, the capacitance should not be changed, since this

could alter the frequency response. However, a higher voltage rating is OK.

"Can" capacitors and other units containing several capacitors are

very hard to find (or are very expensive) and can be replaced with individul

units. However, for can capacitors, disconnect the bad unit but leave

it in place for aesthetic purposes.

Ordering Replacement

Parts:

With the power supplies working properly, it sure looked like the Ranger would

ride again! There was still a long way to go though. The transmitter was

filthy, and there were still other parts that were obviously defective, such as

the drive

control, R13, which was burned out, and

R35,

the modulator screen dropping resistor, which was totally missing.

It turns out that parts such as these are still available, and they aren't that

expensive. However, shipping costs can be a substantial, and the way to

minimize shipping costs is to order all of the parts you will need or MIGHT

need at the SAME time. It is cheaper in the long run to order a part you

might need and not use it than to have to order it later, and pay

additional shipping costs. If the part isn't used, it just goes into your parts

stock for future use.

In addition to R13 and R35, I also wanted to replace all of the

electrolytic capacitors, including those in the power supplies. (The power

supply electrolytics, though not original, and still good, were at least 30

years old.) I also planned to replace any paper capacitors (such as those in

the audio section) with modern ones.

Using the parts list in the manual, I came up

with a list of parts that I would need. For electrolytics in the audio section,

I wanted to keep the values the same so that the audio response would not be

affected. For the power supply electrolytics, moderately larger capacitors

could be used. The high B+ filter capacitor C77 was a 10uf/700V unit. Such

capacitors are no longer available. Instead, two 33uf/450V units were placed in

series with 270kohm/3W film resistors across each one to equalize the voltage

to give the equivalent of a 16.5uf/900V filter capacitor. (Note: Never use

carbon resistors for equalizing resistors! Their negative temperature

coefficient makes them unstable.)

When shopping for parts, remember that larger power values for potentiometers

such as R13 (25kohm/4W) are perfectly acceptable. When the Ranger was made, 4W

potentiometers were standard. My favorite parts supplier,

Mouser Electronics, did have a 25kohm/4W

potentiometer available. The trouble was that it was special order only and

would cost $66!! It turns out that 5W potentiometers are now standard, and a

25kohm/5W unit was available for only $3.61!

For those who may need to replace R13, here is the part number that I used:

Mouser Part Number:

774-026TB32R253B1A1

For R35, which is a 20kohm/50W tapped wirewound power resistor I ordered the

following:

Mouser Part Number:

588-D50K20KE

You will also need two of the following mounting brackets for R35:

Mouser Part Number:

588-9E

Other parts that might be hard to find that I ordered from

Mouser Electronics included the following:

3 Conductor Line Cord:

Mouser Part Number:

562-311007-01

#51 Pilot Lamps:

Mouser Part Number:

560-51

Drive Control Replacement And Initial RF

Test:

With replacement parts on hand, the first thing I did was to replace

R13, the

drive control, which controls the screen voltage on the V4, the

6CL6

buffer/multiplier, and was the last part that needed replacement before I

could check the transmitter for actual RF output. Replacement was fairly

straightforward. Some of the wires to the control were quite short, but I was

just able to make them reach.

Once a new drive control was installed, I reinstalled all of the tubes, set the

band switch to 40m, and placed my Sangean portable shortwave receiver (in CW

mode) next to the transmitter. With the transmitter in tune up mode and the

meter switch set to read grid current, I keyed the transmitter and checked to

see if I could hear the VFO signal in the receiver. No signal was heard and no

grid current was observed, regardless of where I tuned the transmitter. This

meant that either the VFO wasn't working or that it was way out of alignment.

The VFO was going to need some work.

I switched to crystal control, and after inserting a 40m crystal into the

crystal socket I immediately heard the signal on my receiver and observed grid

current. The buffer control and drive controls worked just as they should, and

the signal was very clean and chirp free. I switched to 20m and 15m and still

had plenty of grid current. The crystal oscillator and buffer stages were

working fine.

After connecting a dummy load and Bird wattmeter to the output of the

transmitter, I switched to CW mode and tried tuning up the transmitter. I got

plenty of output and the final, auxiliary coupling, and coupling controls all

worked exactly as expected. Maximum output was about 50W, which was exactly

what it should be. The final amplifier tube and associated circuits all seemed

to be in great shape. The signal sounded clean and the keying was chirp free.

The Ranger was coming back to life!

Power Supply Rebuilding And

Replacement Of R35:

With the RF sections working (except for the VFO) I turned my attention to the

power supply filter capacitors

C77,

C78, C90A/B, and

R35,

the modulator screen dropping resistor.

Though

C77

and C78

had already been replaced and were fine, they were still 30 years old, and I

thought it best to replace them with modern units.

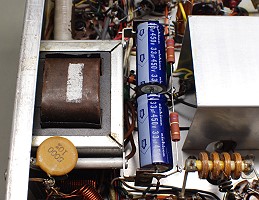

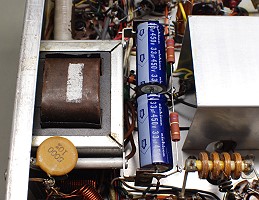

C77

was originally a 10uf/700V capacitor. This was replaced with two 33uf/450V

capacitors in series to give an equivalent capacitance of 16.5uf at 900V. Each

capacitor was shunted with a 270kohm/3W film type equalizing resistors as shown

in the photo below:

Two 33uf/450V capacitors shunted by 270kohm/3W

equalizing resistors were used to replace C77.

Click on the image for a larger view.

Click here for a super detailed

view.

C78

was originally a 30uf/450V capacitor. It was replaced with a 47uf/450V unit.

Capacitors

C90A

and C90B in the keyer/bias supply were originally a two section 15uf/50V

capacitor with both sections wired in parallel. This unit had dried out and was

replaced with a single 30uf/150V capacitor.

R35

was a bit of a problem because it was completely missing from the transmitter

and had been replaced with an arrangement of fixed resistors. I had already

removed these, but had no idea how R35 was supposed to be mounted. However, I

found a copy of the assembly manual on-line

and this showed where R35 should be mounted. I was amazed that, even after

almost 60 years, my replacement resistor was exactly the same size as the

original, and fit beautifully into the original mounting holes! You can see the

new resistor in the photo below:

Resistor R35

Click here for details on

adjusting R35

The tap on the resistor was initially set about half way down. This would

give an initial screen voltage of about 250V maximum on the 6L6GC modulator

screen grids. Final adjustment would be made later.

Click here for details on

adjusting R35. Be sure that the tap is completely loosened when

adjusting it. Do NOT overtighten the tap. The tap only needs to be tight enough

to hold it in place. Overtightening or moving the

tap while not completely loosened will break the resistance wire and ruin the

resistor!

Line Cord And Fuse Holder

Installation:

The Ranger was made at a time when power cords were not grounded. The fuses

were placed in a special plug at the end of the line cord. Modern safety codes

dictate that a grounded 3 conductor line cord should be used on the Ranger. I

had cords in my junk box, but they were large and heavy. Since I was already

ordering other parts from Mouser

Electronics, I just added a new line cord to the order. The cord was 6'

7" long with 18/3 wire. The Mouser part number is below:

3 Conductor Line Cord:

Mouser Part Number:

562-311007-01

I had a large number of cord strain reliefs in stock and found one that would

fit the the cord and the hole in the Ranger. The cord went in easily, but

figuring out where to put the fuse was another matter. The back panel layout of

the Ranger didn't permit the use of a a standard single hole mount fuse holder.

Instead, I had to use a molded base fuse block. I had one in stock,but

Mouser Electronics has them with this

stock number:

Single fuse holder:

Mouser Part Number:

534-3536

This could be squeezed in right next to the accessory socket by drilling a

single hole through the panel. Be very careful when drilling the hole

not to damage anything! I used a 5A slow-blow fuse. See the photo below.

A molded base fuse holder can be squeezed in on the back panel as seen at top

center in this photo.

Click on the image for a larger view.

Click here for a super detailed

view.

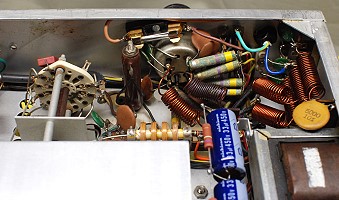

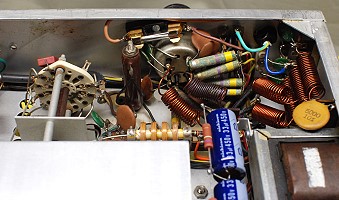

Speech Amplifier Capacitor

Replacement:

There are two double section electrolytic capacitors in the speech amplifier,

C50A/B and C59A/B. These had both dried out and had no capacitance. Though it

is OK to use larger capacitance in the power supply, using larger capacitances

in the audio section could alter the frequency response. C50A/B and

C59A/B were therefore replaced with new capacitors having the same

capacitance. C50A/B was replaced with two 10uf/50V units, and C59A/B was

replaced with two 15uf/150V units. (150V capacitors were used for C59A/B

because they were much cheaper.)

Speech Amplifier

Click on the image for a larger view.

Click here for a super detailed

view.

In the photo above, C50B is the blue capacitor just to the left of the red

postage stamp capacitor at top, and C50A is barely visible under the red

postance stamp capacitor. C59A and C59B are the silver capacitors near the

bottom of the photo, between the two octal tube sockets.

Though I had purchased replacement capacitors for the green paper capacitors

visible in the photo, these were tested with a capacitor tester and were and

found to be good. Since they were moulded in plastic, it was unlikely that they

had deteriorated, so they were left alone. The new capacitors I had purchased

went into my stock to be used elsewhere in the future.

Modulator Testing:

With all of the capacitors in the modulator in good shape, I installed Svetlana

6L6GC modulator

tubes, and decided to test the

modulator. I wanted

to measure its output at flat topping and also its frequency response. The

modulator drives the final amplifier through the modulation transformer, T2.

The output of this transformer is available at the accessory socket X13A on the

back of the transmitter. However, a suitable load must be connected to the

transformer for testing.

The modulator was tested without the 6146 final amplifier tube

installed, and thus without the final amplifier drawing any plate current. This

yields a higher plate voltage on the modulator tubes than during actual use,

but still can still provide meaningful results. The modulator must, however,

be tested with the key down, since this affects the bias on the modulator

tubes. As to R35, my initial adjustment was pretty near the mark, because it

gave a modulator resting current of 72mA during keydown conditions in phone

mode. This was very close to the 75mA minimum

specified by the instruction

manual so I did not, at this time, readjust R35.

The impedance that the modulator drives is the final amplifier plate voltage

divided by the final amplifier plate current. According to the transmitter

manual, the final amplifier should be loaded to 130mA of plate current in phone

mode. At that plate current, the plate voltage would be 500V and the modulator

impedance would be 500V / 0.13A=3850ohms. I had a collection of large 10W-35W

wirewound resistors in my shop, and wired several of these in series and in

parallel to produce a 3750ohm resistor, which is within 3% of the required

3850ohms.

The 3750ohm resistor was connected across the entire secondary of the

modulation transformer at X13A, the accessory socket, and an oscilloscope was

connected across the resistor. A 1kHz sine wave was then injected into the mic

input. The audio gain control was increased until clipping was observed on the

scope, which occurred at 430V RMS, corresponding to an output of

(430V)*430V)/3750ohm=49.3W. The output was reduced to 200V RMS (10.7W output)

and the frequency was varied above and below 1kHz to find the -6dB frequencies

where the output voltage dropped to 100V RMS, half of its value at 1kHz. The

frequencies where the output was 6dB lower than at 1kHz were found to be 110Hz

and 3500Hz.

To properly modulate the 6146 final, 65W/2=32.5W would be needed from the

modulator. Even under real operating conditions, with the final amplifier

operating and with lower plate voltage, the modulator could clearly meet that

requirement. The frequency response of the amplifier was also found to be very

good. Assuming a good microphone, the Ranger should sound great on the air!

VFO Repair And Cleaning:

Initial testing had shown that the VFO was not working, though no problems

could be seen when the lid to the VFO cabinet was removed. To access the rest

of the VFO, the VFO cabinet was carefully removed and two problems were

immediately found:

1. Mice had also moved into the VFO cabinet and the entire area was a mess.

2. The original VFO regulator dropping resistor

R3 had

burned out and had been replaced with a new resistor, one end of which was held

in place with an alligator clip! Evidently, whoever did the repair couldn't

reach that end of the resistor with a soldering iron, so they used an alligator

clip. Not exactly a stable repair, but you have to give them credit for

ingenuity!

The mouse bedding was cleaned out and the entire VFO area was thoroughly

cleaned. As elsewhere in the transmitter, the mice had only moved in, and had

not eaten any wires. The chassis and all components inside the VFO cage were

cleaned with Q-tips and lighter fluid (naptha) and then waxed with Q-tips and

Pledge furniture polish to prevent dust from adhering in the future.

Resistor R3

and the alligator clip were removed and replaced with a new 3W film resistor.

This wasn't easy, since things were very tight, even with the VFO cabinet

removed. (The original repairer probably didn't remove the VFO cabinet, which

would have made soldering one end of

R3

impossible. That's probably why they used the alligator clip.)

After replacing R3, the VFO

came to life. The frequency was not stable, and jumped around a bit. All

connections inside the VFO cabinet were resoldered, but the instability

remained. Most likely, the fixed capacitors had become unstable over the years,

and would have to be replaced to settle down the VFO. Since I planned to use an

external VFO anyway, I left the original capacitors in place, and reinstalled

the VFO cabinet.

Chassis Cleaning:

With most of the electrical restoration done, it was time to worry about the

cosmetic appearance of the Ranger. The chassis, front panel, knobs, and cabinet

were all in need of work, and I decided to tackle the chassis first.

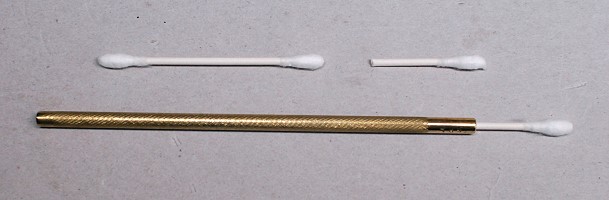

My standard procedure is to first clean as much of the chassis as possible with

a very small rag or piece of paper towel and Ronsonol lighter fluid (naptha).

Over the years I have found that lighter fluid is relatively benign and does a

great job of cutting through grease and other deep grime. (If you are in doubt

as to whether to use the lighter fluid on a surface, test a small inconspicuous

area first.) After as much as possible is done with the rag, I then switch to

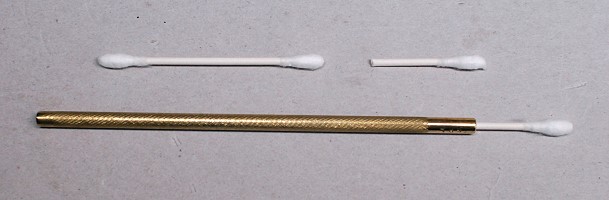

using Q-tips and lighter fluid. I mount my Q-tips in a special brass handle

that I made to hold them, as shown in the photo below:

Brass Holder For Q-tips.

Click on the image for a larger view.

The handle is made of brass and has a hole drilled in one end that provides

a snug fit for the Q-tip. The Q-tips are cut off with a pair of side cutting

pliers and then inserted into the end of the handle, as shown in the photo. The

handle allows me to get into all of the tight places on the chassis that cannot

otherwise be reached. You can control the flex of the Q-tip by how much of the

shaft you leave on the Q-tip. I usually cut my Q-tips in half, and do a whole

bunch at once to save time.

To use the Q-tip, put some lighter fluid on it. If you get it too wet, touch it

to a small rag or piece of paper towel to remove the excess. When the Q-tip

gets dirty, take it out and insert another. You go through a lot of Q-tips, and

it is much like cleaning the floor of your kitchen with a toothbrush, but you

can get to all of those tight places and get them all clean.

I even clean the components (variable capacitors, especially the

steatite/ceramic insulation, fixed capacitors, resistors, and coils (after

carefully testing on a small part of the coil)) this way as well. Yep, the

process is time consuming, but it is about the only way to really get the

chassis clean.

After everything is cleaned with lighter fluid, the entire process is

repeated using Pledge furniture polish to resist dust build-up and give

everything a nice shine.

Finally, after the top of the chassis is done, the entire process is

repeated with the bottom side.

It takes a lot of time, but in the end it is worth it, as can be seen in the

photos.

Front Panel Cleaning

To clean the front panel, the knobs and the front bezel were removed. The panel

and bezel were then cleaned with a small damp paper tower pad covered with

clear coat auto polishing compound. This compound contains the finest abrasive

available, and is normally used to polish the clear top coat applied to

automobiles. It will polish and clean panels without affecting silk screened or

painted makings. Carefully polishing the front panel removed the patina on the

panel and made the silk screen markings stand out very nicely. It also gave the

front panel a glossy finish. After cleaning the panel with the clear coat

polishing compound, a damp pad with only water on it was used to remove all

traces of the compound, and then Pledge furniture polish was used to wax the

panel. Though the front panel has some nicks in it, these give it some

character, and were left untreated. The rest of the panel looks new, as can be

seen in the photo below:

Front Panel After Restoration

Click on the image for a larger view.

Click here for a super detailed

view.

Knob Cleaning And Indicator Insert

Replacement

The knobs were cleaned by first removing the set screws, and then the white

indicator inserts were removed from them with a pair of needle nose pliers.

(Many of these were already missing). The knobs were then scrubbed down with

water and a toothbrush soaked with Soft Scrub kitchen cleaner. The soft scrub

does an excellent job of removing years of patina from the knobs, and the

toothbrush gets into the nooks and crannies of the knobs leaving them very

clean. The knobs were then sprayed and polished with Pledge furniture polish,

which puts the shine back on the knobs.

New white indicator inserts were made from 1/4" white acetal plastic rod I

had on hand. The acetal was turned down to a diameter of exactly 1/8",

with a length slightly longer than necessary. The end of the insert was beveled

very slightly in the lathe. The beveled end was then inserted into the knob and

snipped off with side cutting pliers, which leave the cut end a little out of

round and oval shaped. The insert was then removed, turned around, and the out

of round cut end was pressed into the hole, the oval shape providing the

friction needed to keep the insert in place. Some extra inserts were also

made to keep in stock in case any were lost in the future. A restored knob is

shown in the photo below:

Restored Knob

Click on the image for a larger view.

Frequency Scale Restoration:

The front bezel was removed from the front of the transmitter and then the

plexiglass frequency scale was carefully removed from the bezel. The bezel was

treated the same as the front panel. It was cleaned and polished with clear

coat auto polishing compound and then waxed with Pledge furniture polish.

Though there were some nicks in the finish, these were left in place, since

they gave the bezel some character.

The transmitter frequency scale posed a real problem. Aside from the usual

scratches and gouges in the plexiglas, a semi-circle had been cut out of the

middle of the scale, leaving an ugly rough edge on the inside of the scale, and

some of the major frequency markings were covered with blotches of some sort of

clear glue (super-glue?) All of these problems can be seen in the left photo

below.

The real problem was how to remove the blotches of glue. I eventually found by

careful testing that if I rubbed the blotches with Q-tips dipped in lighter

fluid and then very carefully scraped them with my fingernail, I could slowly

wear away the the blotches, without scratching the plexiglas or harming the

silk screened markings on the scale. It took a while, but I was eventually able

to remove all of the markings. Both sides of the scale were then carefully

polished with with clear coat auto polishing compound and then waxed with

Pledge furniture polish. After the polishing and waxing the scale had most of

its original shine and contrast.

The inside edge of the scale, where the semi-circle had been cut out, was

cleaned and painted with flat black enamel. This kept light from leaking out of

the inner edge and made it almost invisible against the front panel. If you

didn't know it beforehand, you might not notice that the inner part of the

scale was missing. The final results can be seen in the photo below on the

right. Luck was really with me on this one!

Frequency Dial

Replacement:

As mentioned previously, when I first got my Ranger the inner semi-circle of

the clear plastic frequency dial was cut out. I painted the exposed edge flat

black to prevent light from escaping and producing glare. This made the damage

to the frequency dial hard to see, but I still longed to replace the dial with

a new one.

It was a couple of years later that I found out that a company called

Radio Daze makes replacement parts and

dials for many vintage receivers and transmitters. They make a replacement

frequency dial for the Johnson Viking Valiant that will also fit the Ranger.

Their part number is DS-A691 . Below is a direct link to that replacement part:

Radio

Daze Frequency Dial For the Viking Valiant and Viking Ranger SKU: DS-A691

I immediately ordered the replacement dial and in late January of 2018 I

installed the new dial. What a difference it made! The photo below shows the

Ranger with the new frequency dial installed. The Ranger truly is a beautiful

transmitter. Some say it was the best looking transmitter ever made!

Ranger With New Frequency Dial Installed

Click on the image for a larger view.

Click here for a super detailed

view.

Rubber Seal For The Escutcheon:

On some Rangers the rubber seal behind the front escutcheon has rotted and

split. According to Steve Stroschein, W9XF, the following item, available from

WalMart.com, fits like a glove:

Universal

U Channel Rubber Seal Strip 1/32" Opening Edge Trim All Weather Protector

Strip (10ft)

Click here or on the image for a larger view.

Click

here to order from WalMart

White Knob Pointers:

I used white acetal plastic to replace the white knob pointers on my Ranger.

However, Steve Stroschein, W9XF, found that an item available from Electrical

Depot, P/N 114017, called a "Sealing Plug" also works very well. A

bag of 10 sells for $1.55. Cut the plug to length, sand the cut edge, put a dab

of Super Glue on that edge with a toothpick & carefully slide it into the

hole in the knob. You can't tell the difference from the originals.

Deutsch

114017 Sealing Plug Bag of 10

Click here or on the image for a larger view..

Click

here to order from Electrical Depot

Transformer Airbrushing:

After the knobs, front panel, bezel, and chassis had been restored, the Ranger

was looking really great. Besides the cabinet, the only cosmetic problems left

were the high voltage power supply choke

LP1

(which looks like a large transformer) and power transformer

T1.

These were very rusty (especially the laminations), as can be seen in the photo

at left below. They had so many connecting wires (or the wiring was so tight)

that removing them from the chassis was not an option. I could perhaps

paint them with a brush, but that would leave brush marks, and there were areas

I could not get to with a brush. I finally decided that if I thoroughly masked

off the entire chassis I could airbrush the transformers. Airbrushing

would allow me to spray paint down into the nooks and crannies and get them

completely painted, without any brush marks.

As you can imagine, masking off every area of the chassis except for the

transformers was a big job. Masking off the area between

LP1

and

T1

(where the 6146 tube and tank coil are located) was particularly difficult. I

used newspaper and lots of Scotch blue masking tape. I had to cover the

components, but keep the masking away from the transformers so I could spray

their sides. It took several hours, but after the masking was finished I put

the chassis on a large lazy susan and airbrushed the transformers first with a

coat of Rustoleum Professional rusty metal primer (7569), and then with several

coats of gloss black Rustoleum (High Performance Protective Enamel V7579). The

airbrush allowed me to paint every surface of the transformers, even the sides

and backs. After letting the paint dry for a couple of days, I put all of the

tubes in the transmitter and turned it on standby, letting the heat gently bake

the paint. The results were worth all of the work, as you can see in the photo

at right below:

Cabinet Restoration:

As received the cabinet was in terrible shape. It had been spray painted with

some kind of dark blue paint that was chipping and flaking off, and there were

scratches all over the cabinet. It was apparent that a complete paint job was

needed.

Savogran Strypeeze paint stripper was applied to the cabinet and it was

stripped down to the bare metal. Steel wool was then used to remove the last

traces of paint and to thoroughly clean the base metal. The cabinet was then

washed and dried.

There was no hope of duplicating the original cabinet color (I wasn't even sure

what it was supposed to be!), so I decided to paint the cabinet a shade of grey

that matched the front panel. This was obtained by mixing 2 parts gloss black

Rustoleum (High Performance Protective Enamel V7579) to 1 part gloss white

Rustoleum (High Performance Protective Enamel V7592). The cabinet was first

airbrushed with a couple of coats of Rustoleum Professional rusty metal primer

(7569), and then airbrushed with several coats of the final grey. Some of the

rubber feet were missing from the cabinet. I went down to our local music/sound

equipment store and purchased a nice set of feet normally used for a large

guitar amplifier. These fit the cabinet perfectly. The final result was better

than I ever expected, as can be seen in the photos below:

Cabinet After Restoration

Click on the image for a larger view.

Click here for a super detailed

view.

Final Speech Amplifier

Repair:

The transmitter went back on the air June 11th, 2014. I made several CW

contacts, first with crystal control, and then with my digital VFO. I used the

transmitter on CW for about a week and a half and got excellent signal

reports. Satisfied the RF circuits were working correctly, I decided to take

the plunge and operate on AM. However, after fitting a microphone to the

transmitter and testing it into a dummy load, I discovered I had intermittent

audio. I had a devil of a time tracking down the problem, because the

transmitter worked fine with the cabinet off, but would malfunction with the

cabinet on! Finally, after getting it to malfunction with the cabinet on, I

very carefully edged it out of the cabinet a little at a time until I could

very carefully insert a couple of test sockets into the speech amplifier tube

sockets. These allowed me to make voltage measurements from the top side

of the chassis. Measurements finally showed that

coupling

capacitor C52 (500pf) in the speech amplifier was leaking and causing the

second section of the 12AX7 preamplifier,V7B, to saturate. The leakage

resistance of C52 was so high (over 20Mohms) that it could not even be read on

an ohmmeter! Replacing the capacitor, however, cured the problem. I had my

first AM QSO with the Ranger on June 22nd, 2014. (My first AM QSO ever in 46

years as a ham!) Initial reports were that the audio sounded great. The Ranger

was riding the airwaves again!

Back to Dr. Greg Latta's

Electrical Engineering and Amateur Radio Pages

Back to Dr. Greg Latta's

Electrical Engineering and Amateur Radio Pages

Questions, Comments, and E-Mail

If you have any questions or

comments, you can send E-Mail to Dr. Greg Latta at

glatta@frostburg.edu

If you have any questions or

comments, you can send E-Mail to Dr. Greg Latta at

glatta@frostburg.edu

Thanks for stopping by!

Back to Dr. Greg Latta's

Electrical Engineering and Amateur Radio Pages

Back to Dr. Greg Latta's

Electrical Engineering and Amateur Radio Pages If you have any questions or

comments, you can send E-Mail to Dr. Greg Latta at

If you have any questions or

comments, you can send E-Mail to Dr. Greg Latta at