The Center for Product Design and Advanced Manufacturing (CPDAM)

Director's Message

Welcome to the Center for Design and Advanced Manufacturing (CPDAM) at Frostburg State University. Our mission is to be the region's premier hub for product design and development, technology commercialization, and manufacturing.

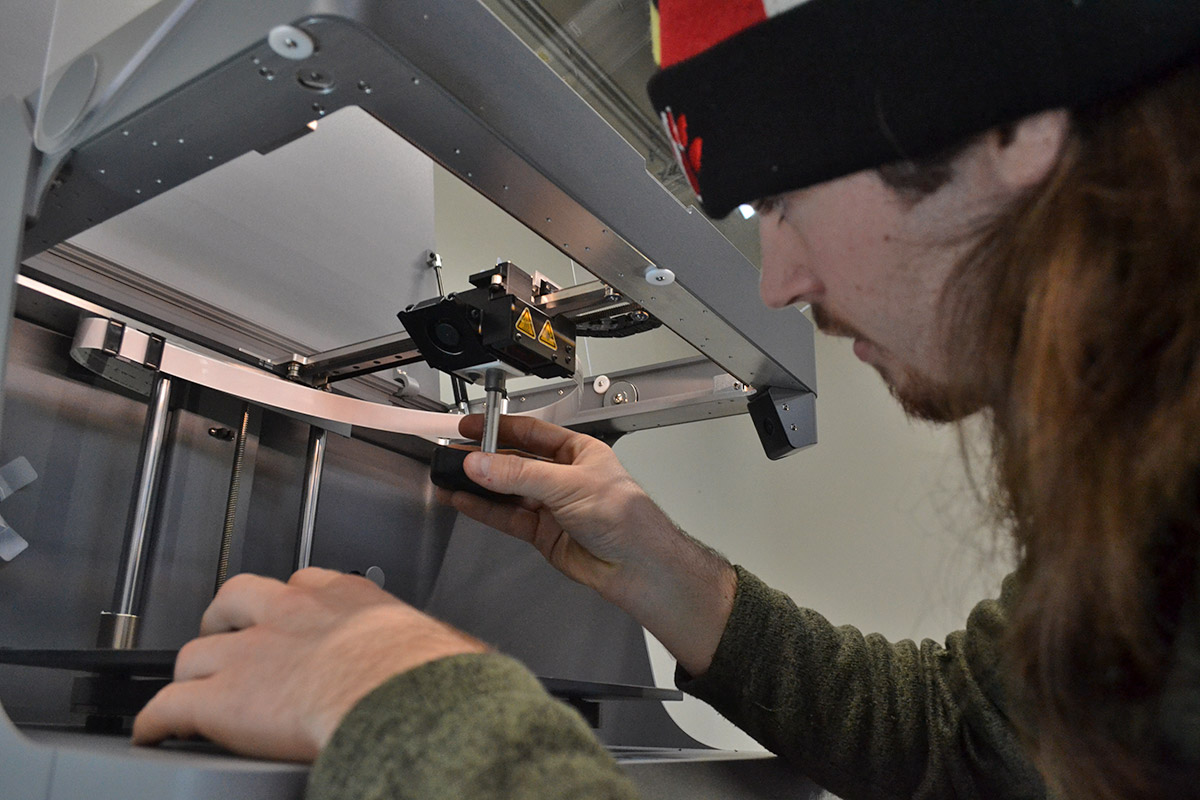

CPDAM is committed to establishing a state-of-the-art equipment and testing laboratory accessible to the region's industry, community, FSU employees, and students. We strive to provide comprehensive services to small, medium, and large businesses, supporting their growth and innovation.

We are dedicated to assisting startup companies in the region with product development, offering expertise and resources to bring their ideas to life. Additionally, we provide training and workshops on the use of advanced equipment and software, benefiting the industry, community, and FSU members.

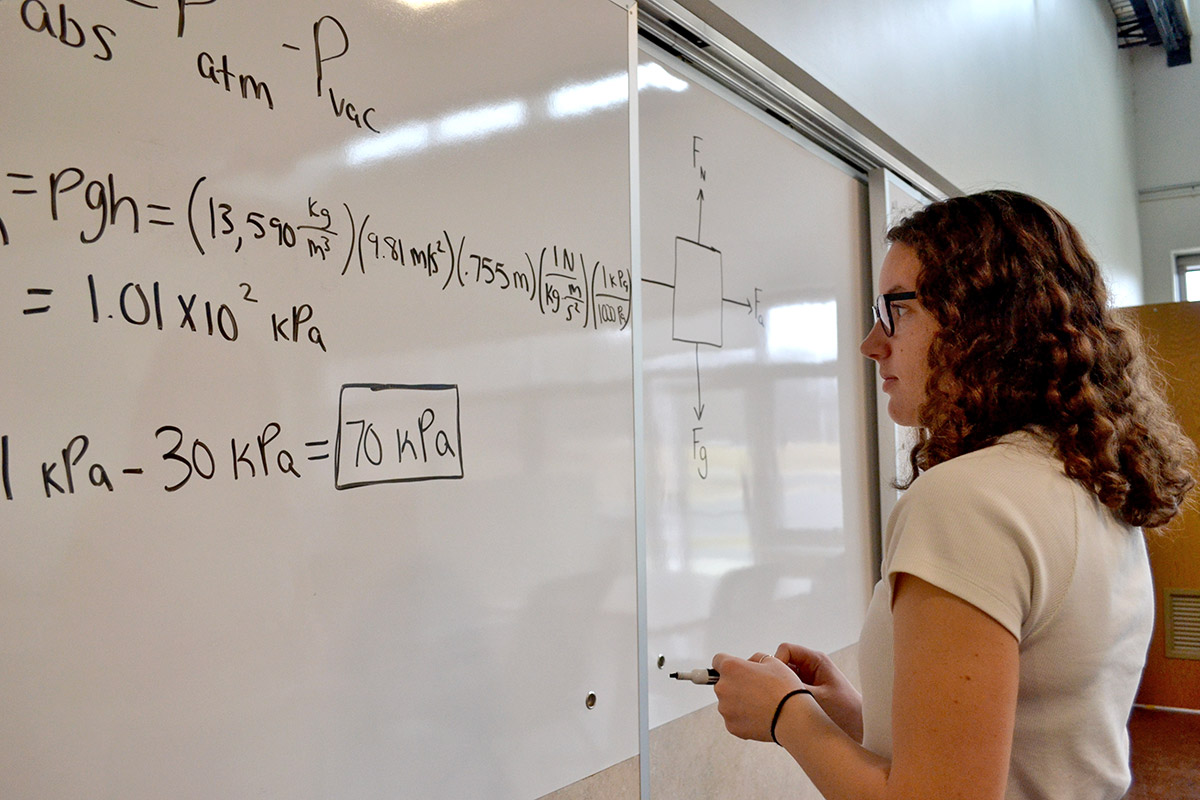

Our center actively engages students in real-world, cutting-edge knowledge in system and product design, and advanced manufacturing. We leverage the technical assets and experience of Frostburg State University's faculty, staff, and students to foster innovation and excellence in every project we undertake.

We look forward to collaborating with you and driving the future of design and manufacturing in our region.

– Dr. Jamil Abdo

About Us

Highly skilled professionals in Western Maryland come together to establish a center for product design and advanced manufacturing, aiming to offer the following:

- To be the region's premier hub for product design and development, technology commercialization, and manufacturing.

- To establish a common testing laboratory for equipment available to FSU students, employees, as well as industry and the broader community within the region.

- To provide a broad array of services to the region's small, medium, and large businesses.

- To assist startup companies in the region with product development.

- To provide training on the use of equipment and advanced software to FSU students, employees, as well as industry and the broader community within the region.

- To engage students in real-world cutting-edge knowledge in system and product design, and advanced manufacturing.

- To extend-the center's technical assets and experience of Frostburg State University's faculty, staff, and students to benefit Western Maryland and the broader region.

Vision

Our vision is to develop an advanced design, manufacturing, and synchrony emerging technology center that will support industrial innovation through system and product design.

Mission

The CPDAM seeks to be a regional leader in industrial innovation and service by providing integrated design and manufacturing technologies in the development of products and systems.

Have a look at the video

- Our Services

- Design Services

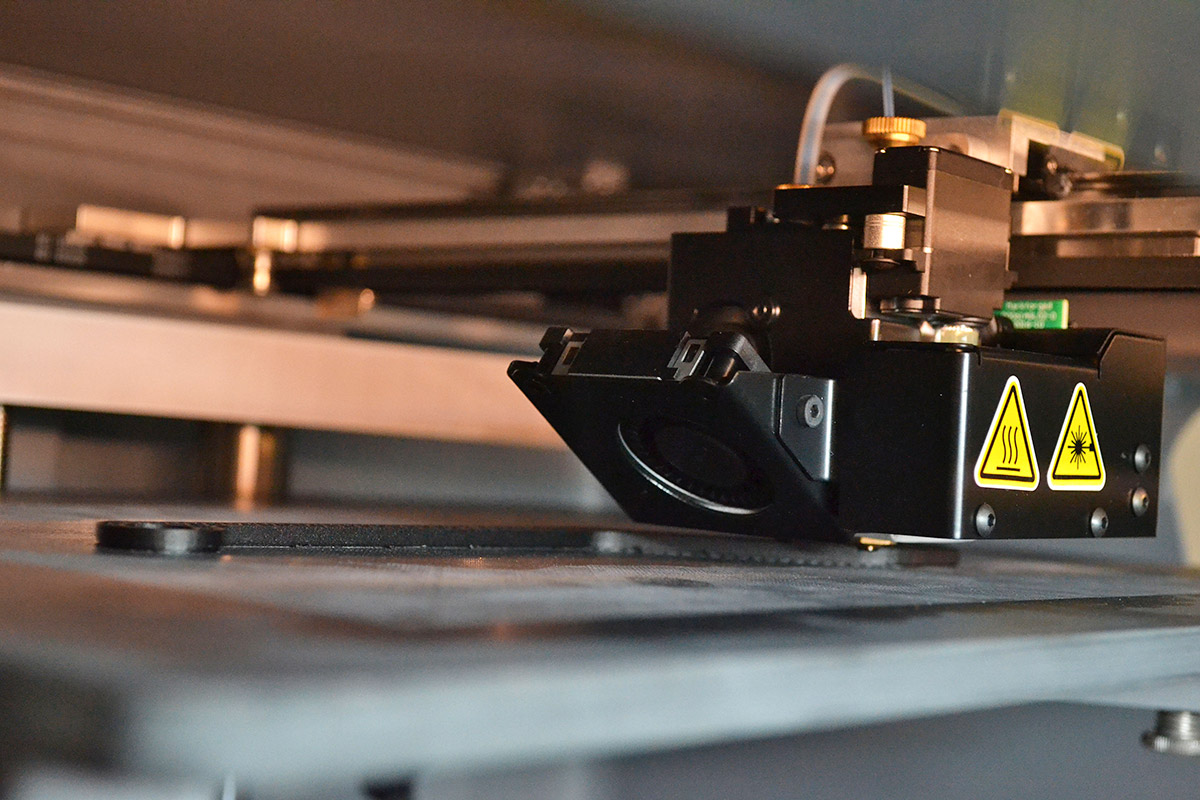

- Metal 3D Printing

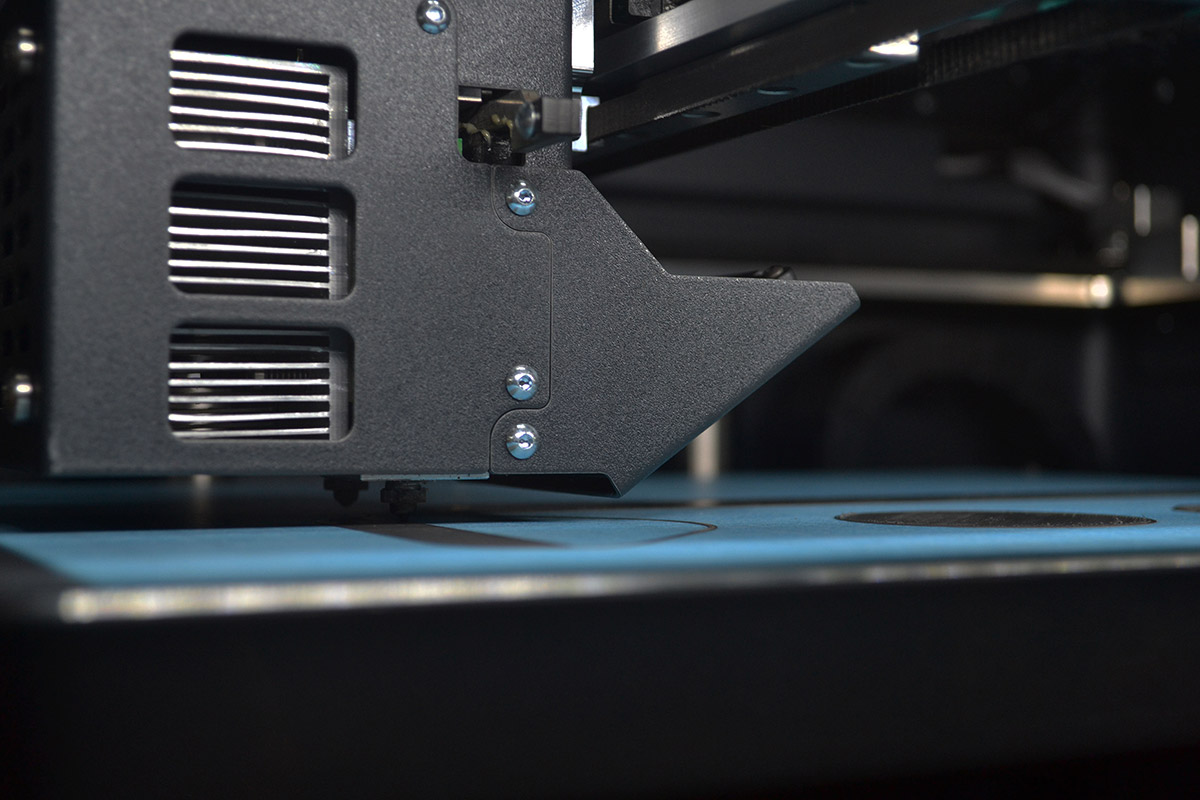

- Carbon Reinforced 3D Printing

- Multi-Polymer 3D Printing

- Multi-Material 3D Printing

- Laser Engraving

- Laser Cutting

- Prototyping

- 3D Scanning

- Tools that we use

- MarkForged X7

- MarkForged Metal X

- Prusa MK3s+

- Prusa Mk3s MMU2s

- Stratasys F120

- Stratasys F370

- Formlabs Form 2

- Software Packages

- Autodesk Inventor

- SolidWorks

- CATIA

- Ansys

- Other (software that comes with 3D printers, e.g., slicer software or firmware)

- Target Customers

- Department of Engineering - FSU

- Students and Researchers

- Startups

- Regional Companies

- Industry Associations

- Investors and Venture Capital

- Projects / Products / Mechanisms

Locking Mechanisms for Solar Vehicles

- Objective: Developed 72 locking mechanisms designed to secure the moving parts of a solar structure, enhancing the stability and functionality of the solar vehicle.

- Key Contributions: Focused on improving stability during operation by securing critical components with precision-engineered locking systems.

Robotic Arm for Football Training Assembly

- Objective: Developed a durable robotic arm for a football training product that ensures effective material selection and 3D printing techniques.

- Key Contributions: Ensured the robotic arm's durability during training activities by using suitable materials and advanced 3D printing technology.

Redesign of Drone Propellers and Guards

- Objective: Worked on the redesign of drone propellers and guards to improve aerodynamic efficiency and safety.

- Key Contributions: Utilized high-performance materials and precision 3D printing to create lightweight yet robust propellers and guards.

Automated Height Adjust ATM Design

- Objective: Assisted in designing an Automated Height Adjust ATM, enhancing accessibility for users of different heights.

- Key Contributions: Worked on material selection and 3D printing for the ATM’s adjustable components to improve user experience.

Design and Fabrication of 3D Lab Specimens for Standard Testing

- Objective: Used 3D printers with metal, carbon fiber, and polymer materials to fabricate specimens for standard mechanical testing and comparison with commercially available specimens.

- Key Contributions: Developed high-quality, customized 3D-printed specimens for testing and analysis, comparing their performance to marketed specimens to assess durability, strength, and material properties.

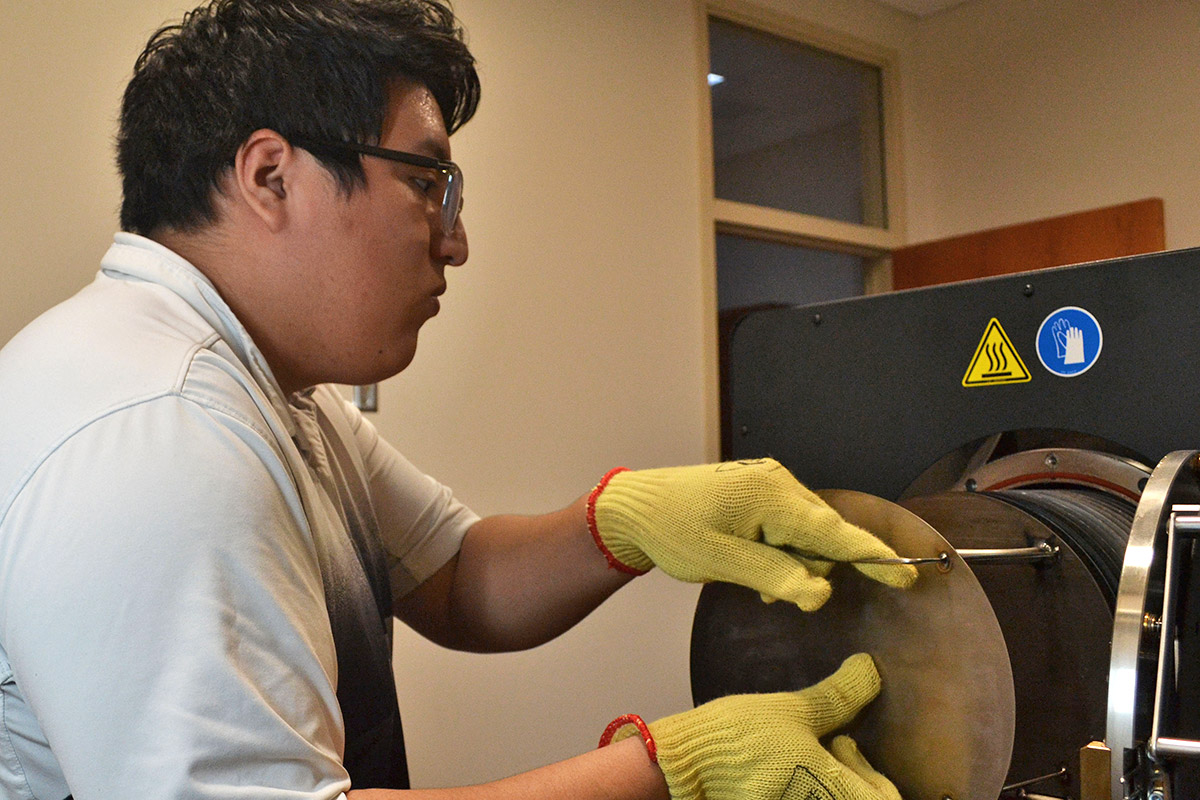

Gallery

Swipe or scroll horizontally to view more photos.

Contact Us

Telephone

240-452-5974

for any inquiries or assistance

cpdam@frostburg.edu

for any business-related inquiries.

Location

5 Technology Drive, Innovative Park

Frostburg, MD 21532

for in-person interactions and consultations.