Engineering Capstone Provides Potential Solution for Icy Sidewalks and Driveways

Feb 26, 2020 9:00 AM

By Sherry White

Anyone who’s been to Frostburg knows that it’s not just a name, it’s a weather statement. So when Frostburg State University engineering students chose a project for their senior capstone class, it seemed fitting to create modular heated tiles to melt snow and ice on sidewalks, driveways and potentially roadways.

“The idea started in our pre-capstone class,” said senior Ryan Miller’19, one of the six-member team. “We asked ourselves, what are some problems that society or Frostburg specifically has and what are some solutions?”

From filters for second-hand smoke to corrosion-resistant paint for ships, they began the arduous process of brainstorming, researching and planning. Eventually, one product came to the forefront.

“Of the 10 or so ideas, we narrowed it down to a blanket-heated driveway,” explained Robert Burns ’19, another member of the student team. “But a heated blanket isn’t sturdy enough to drive on, so we mashed up ideas until we came up with the concept for the heated modular tiles.”

After a great deal of research and collaborating with professionals in the pre-capstone class, the team of students resumed work in the 2019 fall semester as they began the design and construction of the 8-inch x 8-inch octagonal tile system, which they named MelTech.

“We didn’t want consumers to tear up existing driveways and sidewalks, so the tile system is meant to lay on top of an existing surface,” said Burns. “They link together to cover the surface area needed, whether it’s a sidewalk or a bridge. And if one malfunctions or breaks, you just replace that one tile.”

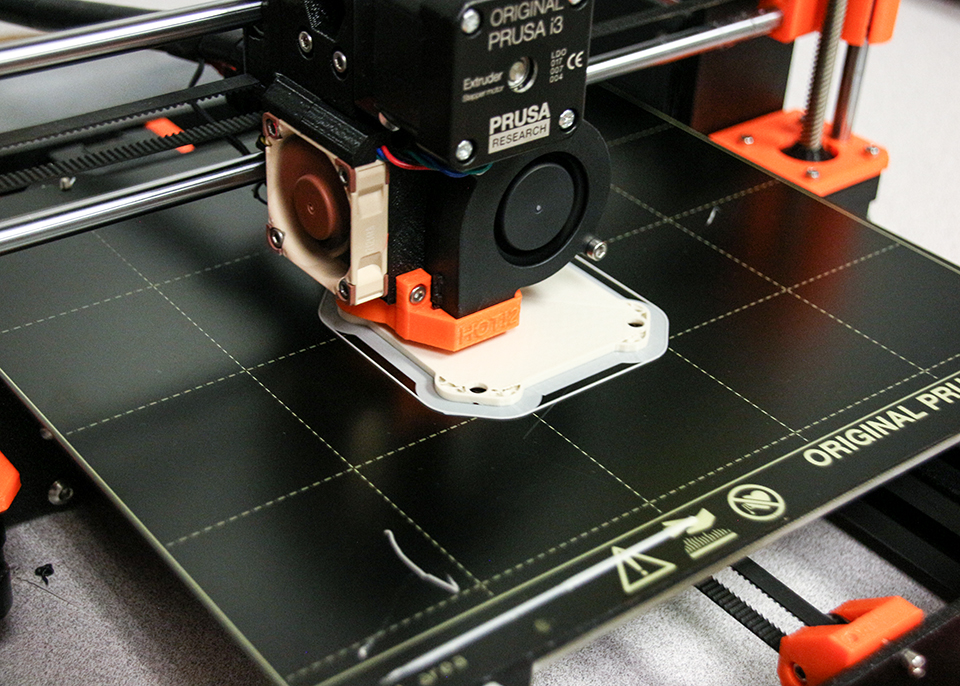

Because the students were limited to the materials available to the classroom setting, the concept for the modular tile was constructed on a 3-D printer on campus. In the case of a real-life manufacturing situation, the team proposed injection molding, which is impact-resistant and can withstand the compression of vehicles driving over it.

Once the structure was printed, the team inserted the electrical heating components. Some assembly required machines offsite, including drilling performed at Phenix Technology, a regional manufacturer of high-voltage test systems and components.

The MelTech tile differs from current snow-melting products in a number of ways. In addition to being sturdy enough to drive over, depending on the process, MelTech tiles could be manufactured in a way that reduced costs for the average consumer. In addition, MelTech tiles are environmentally friendly.

“Salt can be a big problem. Salt increases the rust on cars, it kills grass, it harms wildlife and it deteriorates bridges,” Miller said. “Then the snow thaws and you’re still left with salt everywhere.”

The students provided a concept of design, but they also have ideas for future upgrades if a manufacturer chose to mass-produce their tile.

“We’d really like to see either an app as part of the product, so that it can be turned on remotely, or have the system connected to a weather service, so it would come on according to forecasts,” said Burns. “That way you wouldn’t have to worry about moderating it to stay at temp. It would just take care of itself. It could even have precipitation sensors to detect when it was snowing or have solar panels to help recharge.”

The capstone project even garnered sufficient attention that the students were invited to present at the national Materials Science & Technology conference in Portland, Ore.

“There was a very diverse group of projects and presentations; most were outside the collegiate level, so we were presenting our work right beside people who were out there doing this stuff in real life,” said Miller. “It was a pretty big conference for materials engineers.”

As for the overall capstone experience, Burns and Miller agreed that the challenges and successes of the class helped prepare them for life after graduation.

“I’d only ever done bookwork, so I wasn’t sure where to begin, but the combination of my internship and capstone made everything flow together and make sense,” explained Burns. “Doing this hands-on project helps you see what engineering really is.”

Miller agreed that the capstone class taught students valuable lessons about life after graduation.

“At first the capstone was frustrating because of doing paperwork, getting permission, a lot of waiting,” said Miller. “But looking back at both my Navy internship and this class, it’s more similar than I realized. In the real world, you do have to get permission. You can’t just spend money and build stuff. You have to go through the steps.”

Burns and Miller have plans for after graduation. Burns will begin a job with the U.S. Navy, and Miller has an internship to full-time position at the Naval Warfare Center in Indianhead, Md.

“It turned out a lot better than we thought it would and was pretty cool. Kind of like, ‘Hey, we did this,” said Miller.

The six-member student team included Emmanuel Benyella ’19, Jaren Bohn, Burns, Christian Healey ’19, Miller and Lane Mosser ’19. The capstone project was led by Dr. Zhen Liu, materials engineering professor, national leader in composites engineering materials who is serving session chair for American Institute of Chemical Engineers. The project is co-advised by Physics and Engineering faculty members Dr. Oguz Soysal (electrical engineering), Dr. Julie Wang (mechanical engineering), Dr. Eric Moore ’00 (physics), with technical support from in FSU’s Additive Manufacturing Lab from lab manager Duane Miller and student Katelyn Hamilton; and from the manufacturing department of Phenix Technologies in Accident, Md.. Financial support came from the FSU Undergraduate Research Travel Award and the Provost’s Experiential Learning Enhancement Fund.

Situated in the mountains of Allegany County, Frostburg State University is one of the 12 institutions of the University System of Maryland. FSU is a comprehensive, residential regional university and serves as an educational and cultural center for Western Maryland. For more information, visit the Frostburg State web site or the FSU Facebook page. Follow FSU on Twitter @frostburgstate.Engineering students working on their capstone project took inspiration from their frosty Frostburg surroundings in developing modular heated tiles to melt snow and ice on slippery surfaces.

A 3D printer prints components of the MelTech system.

A 3D printer prints components of the MelTech system. The heating components inside the MelTech tile are soldered.

The heating components inside the MelTech tile are soldered.  After the heating component is complete, a diamond plate is secured to the top of the MelTech tile.

After the heating component is complete, a diamond plate is secured to the top of the MelTech tile.